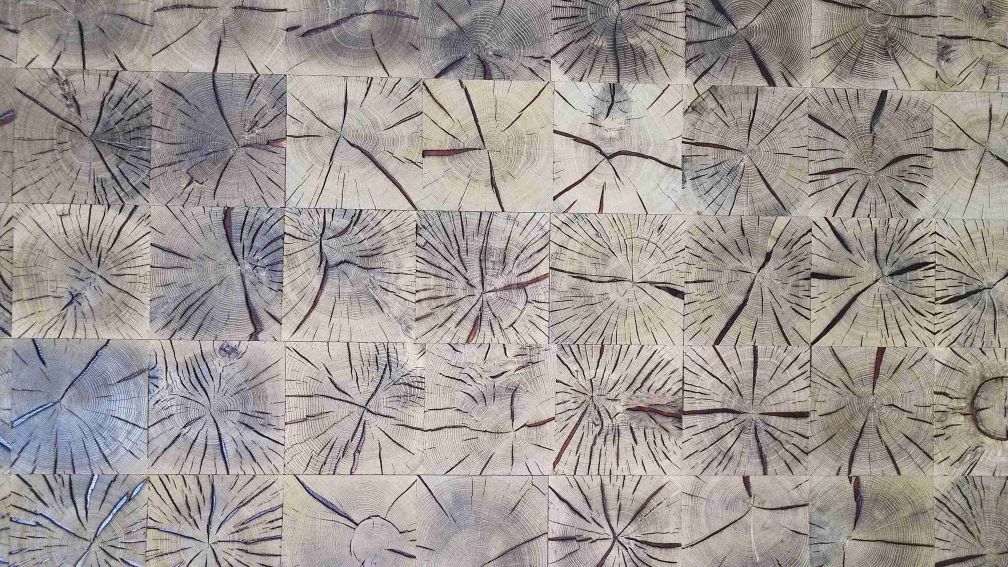

What is End Grain Flooring?

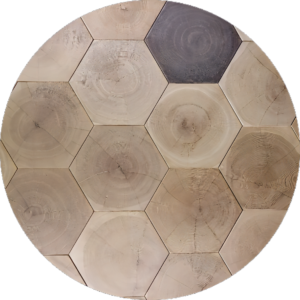

Also called “wood-block” flooring, end-grain floors are made of tiles cut from timber ends. Because the cuts are made across the board, the end grain is exposed on the face of the tile, just as it would be on a chopping block.

Also called “wood-block” flooring, end-grain floors are made of tiles cut from timber ends. Because the cuts are made across the board, the end grain is exposed on the face of the tile, just as it would be on a chopping block.

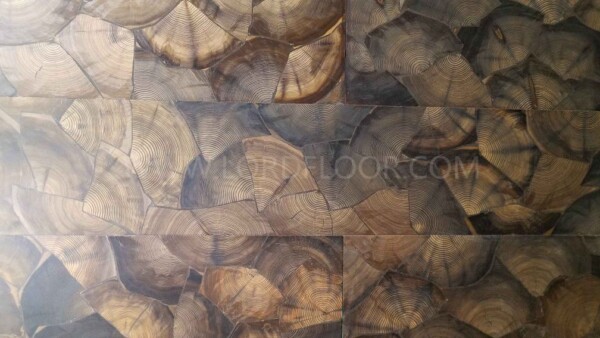

End Grain floor is a special product in LORD PARQUET Family, different from normal solid hardwood and engineered floor, End grain remains the most visible part of the annual ring of a tree.

Every ring tells a whole year story and we think once it is been made into the flooring and stepped into people’s lives, The tree begins a new life with its new owner.

By the way, End grain material mostly comes from the roots of a tree, which sometimes are wasted from the sawmills.

Eng grain floors are mostly been used in that areas that need special designs. Such as lobby of a hotel villa, wall panel / vintage style bars/lounge.

Make this into the new high-end product not only a nice and unique design for flooring, wall panel, furniture, It also saves the wood(world) for the environment-friendly purse.

End grain floor remains the most beautiful natural beauty of the timber, because of this, End grain floor is really difficult and complicated to stabilize its form, it could take up to 2 years to air dry the root timber in the air, and there will be a huge wasting during kiln dry, sizing/ TnG notching and coating process. Thus, the price of this floor is a bit expensive compare to normal wooden flooring.

We can do end grain floor into: Plank / chevron / herringbone / customized size

End grain block in dimension: 7”/7.8”.

Top layer Thickness in 2mm / 3mm.

smooth or open grain UV coating pre-finish or hard wax oiled Prefinish

Natual / carbonize / stained.

Share This Story, Choose Your Platform!

Description

320×320×15/2mm

1800×300×15/2mm

1800×300×15/2mm

Video

Floor Pictures

Q&A

A: We accept L/C or T/T. The L/C should be irrevocable and payable at sight. If it is T/T, 30% down payment is request to be made according to the proforma invoice we issued. Then the balance payment can be done after receiving copy of Bill of Lading stamped shipped on board, Invoice and Packing List by email or fax.

A: Most containers take 4-6 weeks from time payment is received. There is a chance that it may take longer because of factors beyond our control. For example, security measures and Border Protection could possibly delay shipment.

A: It means some special installation styles like: Herringbone parquet, Chevron parquet, Mosaic parquet, Plaint weave… Recently, we have developed some new free installation flooring like Wood Gravel parquet, 3D style parquet and Cock tail flooring. You can also check our website:www.lordparquet.com

A: Normally, for “running installation” the waste is about 3-5%. However, with the “free installation (herringbone, mosaic)”, it’ll be up to 7-10%. The waste also depends on worker’s skill level and the layout of your room.

A: For domestic customers, you can go to our retail stores or check with our distributors in different cities. For international customers, we have distributors around the world such as U.S, U.K, French, India, Philippine etc.. Also you can scan our website and contact us directly by email, if you have any question and requirement. We reply your questions within 24 hours.

| LENGTH | WIDTH | THICK | GRADE | Average Length |

| 300-1200mm ( 1′ – 4′ ) | 72mm ( 2-4/5″ ) | 18mm ( 3/4″ ) | Selected | 650mm |

| 300-1200mm ( 1′ – 4′ ) | 90mm ( 3-1/2″ ) | 18mm ( 3/4″ ) | Natural | 650mm |

| 300-1200mm ( 1′ – 4′) | 120mm ( 4-3/4″ ) | 18mm ( 3/4″ ) | Selected | 650mm |

Multiply Wide Plank Engineered Flooring

| LENGTH | WIDTH | THICK | VENEER | GRADE | Species |

| 1860mm | 189mm | 15 mm | 4mm | Select & Natural | Oak/Walnut/Teak |

| 1860mm | 189mm | 21mm | 6mm | Natural & Rustic | Oak/Walnut/Teak |

| 2200mm | 220mm | 19 mm | 4mm | Natural & Rustic | Oak/Walnut/Teak |

| 2200mm | 240mm | 21mm | 6mm | Rustic | Oak/Walnut/Teak |

| 2200mm | 260mm | 21mm | 6mm | Rustic | Oak/Walnut/Teak |

Heating System Engineered Flooring

![]()

| LENGTH | WIDTH | THICK | VENEER | GRADE | Species |

| 420mm | 70mm | 10 mm | 4mm | Select & Natural | Oak/Walnut/Teak |

| 490mm | 70mm | 10mm | 4mm | Select & Natural | Oak/Walnut/Teak |

| 450mm | 90mm | 10 mm | 4mm | Select & Natural | Oak/Walnut/Teak |

| 600mm | 90mm | 10mm | 4mm | Select & Natural | Oak/Walnut/Teak |

| 900mm | 90mm | 10mm | 4mm | Select & Natural | Oak/Walnut/Teak |

We are using Denmark WOCA Oil for our Engineered wood flooring products, for different color and finish, we use different products of WOCA.

Water based stuff: 401

UV Bottom Oil (Natural color): No. 501

UV Bottom Oil (White color): No. 601 5% white pigment

UV Bottom Oil (Natural color): No. 603 2.5% white pigment

UV Face Oil (Natural color): No. 506 Glossy: 12-18%

UV Face Oil (Natural color): No. 507 Glossy: 8-12%

UV Face Oil (Natural color): No. 508 Glossy: 5-8%

UV Face Oil (White color): No. 605 5% white pigment Glossy: 12-18%

UV Face Oil (White color): No. 606 2.5% white pigment Glossy: 12-18%

Woca Natural Oil WOKA 1503

a. Russian oak is more premium grade, clear surface, less knots. less color variation. European Oak looks much rustic. So normally our AB grade is Russian oak and CD grade is European oak.

b. Russian oak has less tannic acid inside, and European oak has more, this will only influence if your color need to do fumigation, after fumigation, the appearance will be different. normally European oak looks better.

c. for unfinished floor, the grain looks slightly different.

Detail please check: