What’s the difference between traditional bamboo and strand-woven bamboo flooring?

How do we get material from bamboo?

After harvesting the mature bamboo stems are split in longitudinal direction and the louter skin is removed. The strips naturally have a light yellow colour (natural), but can be steamed and thermally treated for a light brown colour (carbonized).

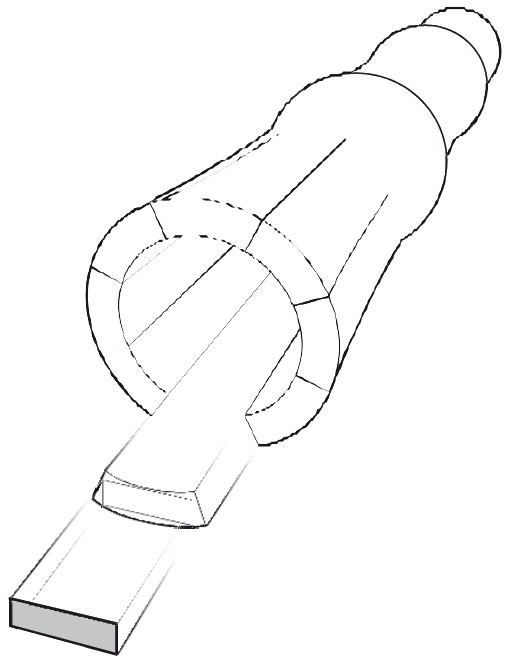

After treating and drying, the strips are ready to be connected in several ways to make the final product.

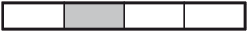

Plain Pressed

Horizontal

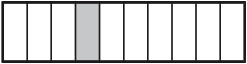

Side Pressed

Vertical

Strand-Woven

Compressed

Strand-woven bamboo is much harder than traditional bamboo, even harder than the best tropical hardwood species. But it also loss the appearance of traditional bamboo because it’s compressed. Strand-woven bamboo can be used both indoor and outdoor, mostly used for outdoor decking for it’s anti-decay, water proof characteristic.

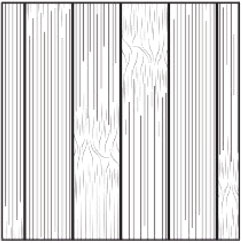

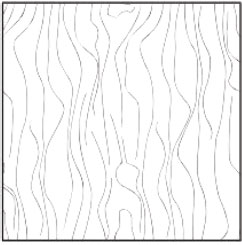

Surface Grain of Bamboo Floor

Plain pressed

Side Pressed

Strandwoven

Solid Bamboo Flooring – Horizontal Bamboo

Solid Bamboo Flooring – Vertical Bamboo

The Engineered Bamboo strip Flooring have tongue and groove and consist of 2 layers: a 3-4mm bamboo top layer and a multiplex (7-11mm) sub layer. With this construction, the floor board is extremely stable and with the thick top layer also very durable.

For strand-woven bamboo, we can also produce both Natural color and Carbonized color.

Natural Color

Carbonized Color

To choose which color, depends on what the market favorite of.

But in some very wet area, we Don’t recommend to use “Natural color” because Natural color bamboo have a lot of sugar inside, it’s easy to get moss or be attacked by termite.

So, a lot of clients choose carbonized bamboo.