Characteristics of Wood for Flooring

In doing some research about the benefits of using hardwood flooring in a home one answer that’s always provided is ‘durability’. Granted, wood is one of the strongest materials available, durable enough to build the entire home out of in fact. That being said there are some questions that should be examined when identifying the different levels of durability. Are all wood flooring products the same strength? Are they durable to physical collisions or more internally stable? Does the strength affect how difficult the wood is to install?

The truth is these questions are answered in what becomes known as the characteristics of the specific wood used in the home. In addition to finding a wood with the looks and style that match your appeal, it is very important to check these characteristics to see how well the material will stand up to scratches, how hard it will be to cut and nail if a DIY job, and if it should be installed in a humid climate or a moisture-rich room.

Janka Hardness

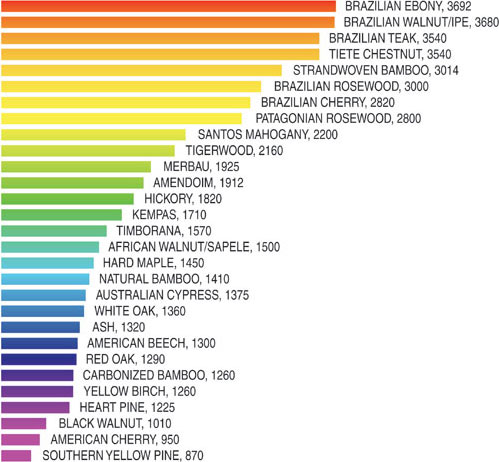

The Janka Hardness Test puts a definitive number on how resistant to scratches and dents a particular wood species performs. The scale rates the definitive hardness of the material as tested by the force required to embed a .444” steel ball half it’s diameter into the wood. Flooring species that have a higher Janka Hardness number will harder woods and thus more durable in the home. The Red Oak species is said to be the benchmark for wood with a Janka rating of 1290. That is by no means the hardest wood available (Brazilian Walnut 3684, Tigerwood 1850 to name a few) but it does dictate whether a material is above or below average hardness. Referring to the Janka scale is useful when comparing two different woods such as American Cherry (950) and Hard Maple (1450) when knowing your home has heavy foot traffic, pets, multiple pieces of heavy furniture, etc.

Janka Hardness Scale for Most of the popular wood species:

Air-dry Density

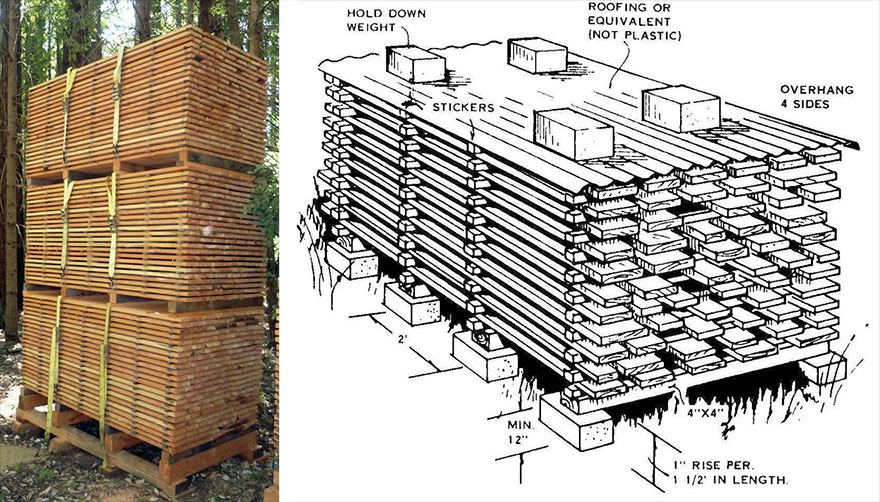

Since wood will absorb or desorb moisture until it finds an equilibrium with its surroundings, it is dried before being manufactured into flooring pieces. This makes sense because of all the moisture the wood has absorbed while out in the timbers and the rapid (and damaging) equilibration that would occur in a much drier home. Air drying involves the process of simply letting the timber remove moisture on its own, with the assistance of an open air environment and a steady supply of air flow.

The other form of drying is via a kiln which can be done to any set moisture content and at a much faster pace. Since there are so many variables involved with kiln dried settings, the density of wood is determined from the air-dry manner. Air-density is measured in g/cm3 and the higher the number, the more stability the wood will offer.

Moisture Content

While the moisture content of the wood will have various high peaks and low ranges as it reacts to the air over the years, proper drying before installation will limit the damage caused by these fluctuations.

Nail and Screw Difficulty

Bending Strength

Bending strength determines the load that wood can withstand when applied perpendicular to the grain. This is not so much an issue in flooring where a subfloor will help distribute the wood but is important in an application like decking boards which are laid across beams and may bow if not of an adequate bending strength.

Stability

Dimensional stability is a reading that combines many factors together to ultimately determine a woods resistance to environmental changes from temperature, humidity, moisture, etc. All wood undergoes changes (expanding and contracting) based on these fluctuations but stability determines just how much. A lower number like .00144 (natural bamboo) indicates a more resistant wood than a higher number like .00411 (true hickory).