WPC Flooring

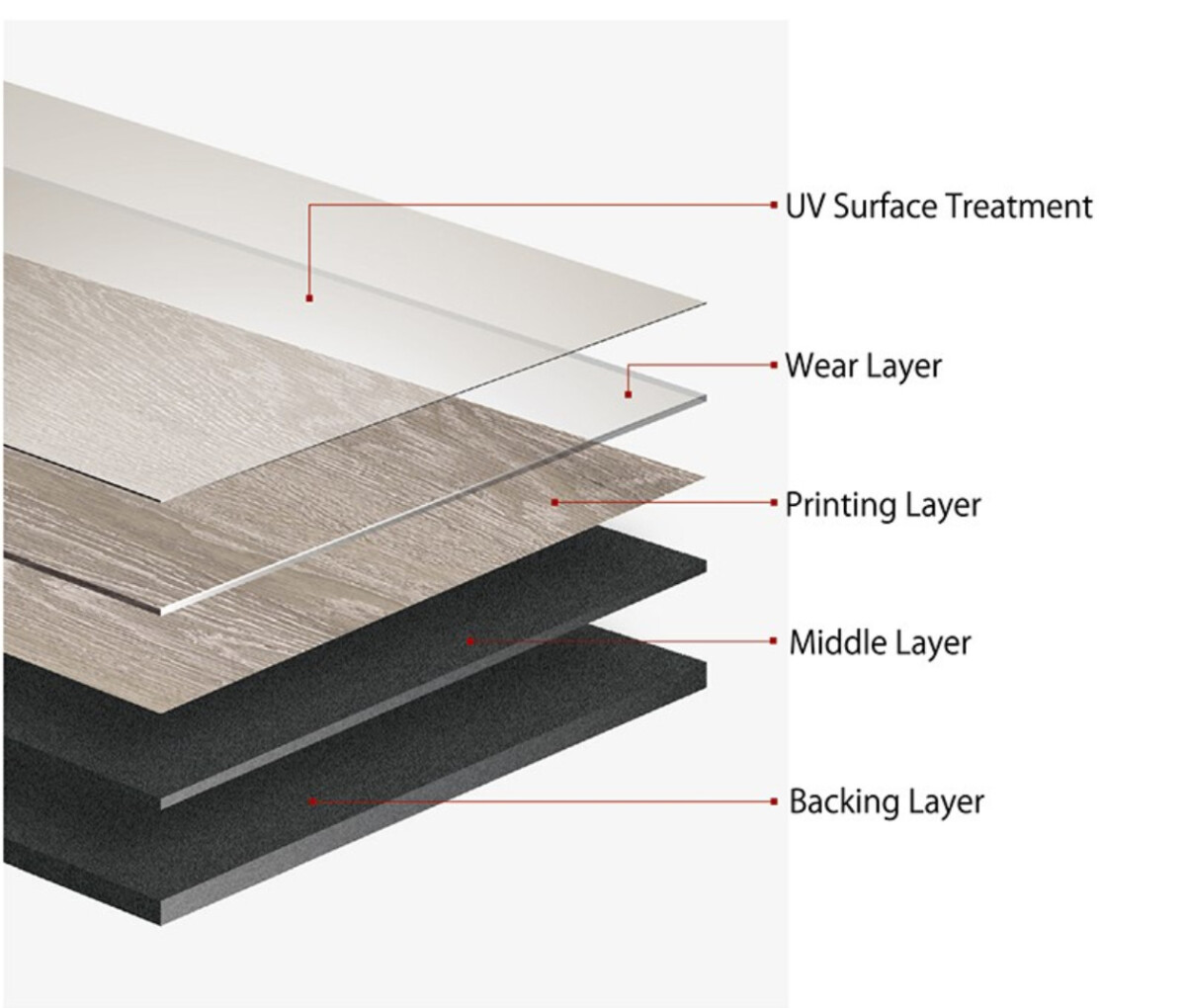

WPC, or Wood Plastic Composite Flooring, is a premium luxury vinyl flooring product that combines the strength of hardwood with the resilience, maintainability, and affordability of virgin PVC. As with other luxury vinyl flooring products, WPC is comprised of several layers: a printed wear layer, virgin PVC core, and high-density iXPE foam backing.

Share and Choose Your Platform!

Description

| Planks Specification: | 6inch x 48inch (144mm x 1209mm) 7inch x 48inch (180mm x 1230mm) 9inch x 48inch (219mm x1209mm) |

|---|---|

| Thickness: | 6.0mm/8.0mm |

| Planks surface embossing: | special deep wood |

| Surface glossiness: | matt(5-8°) / semi-matt(8-12°)/glossy(18-22°) |

| Material: | 100% virgin material |

| Backing: | IXPE/EVA |

| Tiles Specification: | 12inch x 24inch (300 mm x 600mm) 18inch x 36inch (448mm x 903mm) |

| Click System: | unilin/vanlige click |

| Wear Layer: | 0.3mm/0.5mm |

| Surface coating: | UV coating |

| Tiles surface embossing: | carpet texture / slate |

| Round edge beveling: | 0.5mm wear layer available |

| Quality: | CE&ASTM certificate |

- Waterproof: This is what makes both rigid core and WPC vinyl so popular. It’s perfect for business owners, pets, and water-prone areas.

- Great for uneven subfloors: Rigid core is designed to be installed over any existing hard surface, including tile, even if it’s imperfect or not completely level.

- Ultra-durable: That SPC core makes this vinyl flooring the most durable vinyl flooring option out there.

- Realistic wood and stone look: Top-end vinyl floors mimic natural materials better than ever before. SPC vinyl is the cream of the crop, so the visuals are usually incredibly convincing and beautiful.

- Low-maintenance: Keeping your floor looking fabulous is so simple. Occasionally vacuum and mop, and you’re all set.

- Easy installation: Rigid core luxury vinyl tiles and planks are easy to install yourself with most options interlocking and floating over your existing surface.

Q&A

Also, check the testing report for the ”Thermal conductivity and thermal resistance” And “Dimensional stability and curling” Seems like it is fine under 70-degree testing, but I will double-check with the factory.

The factory has achieved many certificates and tests for these products, I attached all of them to you, They haven’t written an official warranty file, but from those we can see the limit of this product by the testing reports.

A: 2 times UV coating are applied on top of the anti-scratched wear-layer

You should import it the same as the SPC/WPC/LVT products, which is the same as what you bought before from us.

A: Normally one version is 2440 x 1220mm, so that means in 3sqm will have no repetition.

A: If the color you choose from the factory has stock, MOQ is 500sqm. If not, MOQ is 1500sqm.

A: Different widths, prices are the same. Because they just cut from a 1220mm wide pcs.

A: The Patent is Valinge 2G/5G fee, if you want us to stick a patent label on the box, that is necessary.

A: Just the way of production is different, Cylinder EIR are made when the extrusion, Normally SPC does not need to do a hot press. While hot press EIR will have to do EIR during the hot press, it can be applied on SPC, just a bit complicated.

A: Normally we do an embossed surface, EIR (Embossing with registered) means the embossment goes with the texture of the printing, which looks like a wire brush. For example, if on the printing design there are knots, the embossment also has a knot sinking, if the printing has a “crack” the embossment also has a crack feel. That is the generic wood grain look as you mean I think.

A: Factory normally guarantees that the structure is a lifetime. But the surface depends on the traffic which is 15 years and 25 years for commercial and residential. Same as our wooden floors.

A: I think it’s better to send you samples to see the difference. I don’t have samples with me, but even taking photos is not easy to describe.

The feet definitely feel softer than plastic and should feel like wood, but I don’t know how it sounds. But we can check the testing report by the factory too I think.

Yes, it is better to come with a IXPE foam backing . Or we see some customer of the factory they do beach backing, cork backing or they even do oak backing (both 2mm top and 2mm bottom)

The cost for prefinished is $1,50/sqm for this product, this factory doesn’t have too much experience of doing UV coating, sometimes they have to purchase more primer or top coating. But don’t worry about the colour consistency, LORD’s QC people are watching all the colours for any orders. 3-4 colour/20ft containers will be fine. The MOQ for each colour is 500sqm.

I will email you the price for 190 next mail.

Also, check the testing report for the “Dimensional stability and curling”.